The f02 error code in a Goodman furnace typically means the pressure switch lacks enough vacuum to close, preventing the furnace from running. A blocked flue, a weakened induced draft motor, or faulty switch contacts can cause insufficient vacuum on the pressure switch.

These factors represent only a handful of potential reasons for low vacuum on the pressure switch.

Possible Causes For Goodman Furnace Code F02

| POSSIBLE CAUSE | HOW TO FIX |

| Blocked flue or inlet air pipe, blocked drain system, or weakly induced draft blower. | Inspect the flue or inlet air piping for blockage, proper length, elbows, and termination. Check the drain system. |

| The pressure switch hose is blocked, pinched, or misconnected. | Inspect the pressure switch hose. Repair, if necessary. |

| Incorrect pressure switch setpoint or malfunctioning switch contacts. | Correct pressure switch setpoint or contact motion. |

| Loose or improperly connected wiring. | Tighten or correct the wiring connection. |

Regularly checking and maintaining your furnace components is key to preventing issues. If you encounter problems, inspect the flue, inlet air piping, and pressure switch hose for any blockages or improper connections. 🔧

Troubleshooting Steps For Goodman Furnace Code F02

Verify Inducer Motor Operation

Confirm if the inducer motor is running; it should create a vacuum to engage the pressure switch.

Should the motor not be operational, the pressure switch may not close due to the lack of a vacuum. 🔄

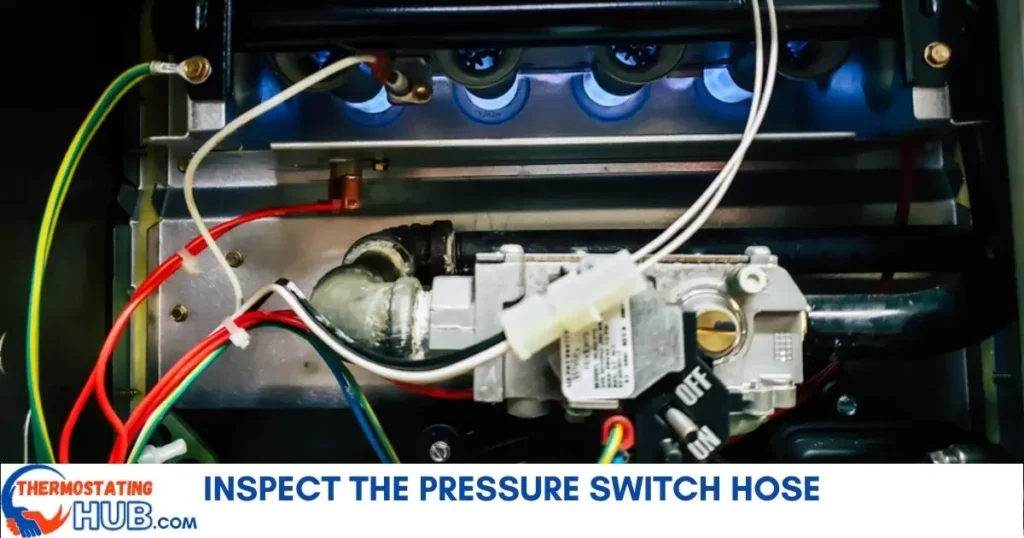

Inspect the Pressure Switch Hose

Look at the tube connected to the pressure switch. Check for blocks, pinches, cracks, or if it’s not connected properly. If there’s any issue with the tube, the pressure switch won’t work like it should.

Read also: Trane Thermostat Says Waiting

Check the Flue and Induced Draft Blower

Confirm the flue is clear and unblocked. Double-check the induced draft blower to ensure it functions correctly; a weak blower might not generate enough vacuum for proper operation. Regular maintenance is crucial for optimal performance.

Check Pressure Switch Settings

Verify the pressure switch’s setpoint is correct. Malfunctioning switch contacts can also hinder proper closure. 🔍

Verify Wiring Connections

Make sure all wiring connections are secure and properly attached. Loose or incorrectly connected wires can disrupt the pressure switch’s operation.

Confirm Vent Motor Operation

Confirm the small vent motor is working; it plays a role in generating a vacuum.

Check Vent and Intake:

Look for blockages in the vent or intake.

If there’s a connected drain, ensure no water backup in the hoses.

Pressure Switch Test:

Disconnect the rubber hose from the inducer, keeping it attached to the switch.

Activate the thermostat for heat, then suction on the hose to listen for a clicking sound from the switch and ignition of burners.

Pressure Switch Bypass Test

Let the inducer start and use a jumper wire to bypass the pressure switch. This simulates the switch being closed and helps check if the furnace ignites. 🔍

By using advanced troubleshooting techniques

Specialized tools like a vacuum manometer or Magnehelic gauge are needed for advanced troubleshooting.

- Connect the gauge between the inducer and the pressure switch to measure the vacuum.

- Verify if the vacuum meets the required amount to “close” the switch or exceeds the vacuum needed for it to “open” (as marked on the switch label).

Read also: Low Suction Pressure High Head Pressure

Replacing the Pressure Switch

If the problem continues, consider swapping out the pressure switch; it’s not too pricey. If switching the pressure switch doesn’t fix things, the next thing to look at could be replacing the inducer assembly.

Keep in mind that regular maintenance can prevent such issues. It’s a good idea to schedule a yearly check-up for your heating system to catch any problems early on. Taking these small steps can save you from more significant headaches down the line. Stay warm and worry-free!

Mastering Goodman Furnace Code F02: Expert Maintenance Strategies

Goodman Furnace Code F02 may seem mysterious, but with these pro tips, you can ensure your system stays in optimal condition:

Code Decoding:

Understand that Goodman Furnace Code F02 typically points to a motor or capacitor issue. This insight helps you target the specific components for inspection.

Motor Inspection:

Start by examining the furnace motor for signs of wear, damage, or obstruction. Lubricate moving parts and replace the motor if it’s beyond repair.

Capacitor Check:

Assess the condition of the capacitor. A faulty capacitor can hinder the motor’s performance, triggering the F02 code. Replace any capacitors showing signs of leakage or swelling.

Electrical Connections:

Ensure all electrical connections are secure. Loose or damaged connections can disrupt the functioning of the motor and contribute to the F02 alert.

Voltage Verification:

Verify that the motor is receiving the correct voltage. Inadequate or excessive voltage can lead to motor issues and trigger error codes.

Thermostat Evaluation:

Check the thermostat settings and operation. Incorrect thermostat settings or malfunctions can affect the motor’s operation and lead to the F02 code.

Airflow Assessment:

Confirm that there are no obstructions affecting airflow. Restricted airflow can cause the motor to overheat, triggering the F02 alert.

Regular Maintenance:

Implement a routine maintenance schedule, including cleaning filters and inspecting components. Regular upkeep can prevent issues that may lead to error codes.

Professional Assistance:

If troubleshooting doesn’t resolve the F02 code, seek assistance from a qualified HVAC professional. They can perform a comprehensive inspection and provide accurate diagnosis and solutions.

Documentation Review:

Consult your furnace manual for specific information on the F02 code. It may offer additional insights or steps tailored to your furnace model.

Following these pro tips, you can unravel the secrets behind Goodman Furnace Code F02 and take proactive measures to keep your system operating at its best.

Navigating Goodman Furnace Code F02: Pros and Cons Unveiled

When it comes to the Goodman Furnace Code F02, there are both advantages and disadvantages to consider.

| Pros | Cons |

| Quick Troubleshooting | Potential Disruption of Heating |

| Clear Error Indication | Limited Information Display |

| DIY-Friendly Resolution | Professional Intervention Needed |

| Helps Prevent Further Damage | Specificity of the Issue |

Goodman Furnace Code F02 Decoded: Key Takeaways for Seamless Operation

Decoding Goodman Furnace Code F02: Tips for Smooth Operation

If you’re dealing with the Goodman Furnace Code F02, it’s vital to understand the key points for a trouble-free experience. This code, F02, is significant for system diagnostics and can significantly impact performance.

F02 primarily signals a potential gas valve circuit issue. It indicates a communication problem between the gas valve and the control board. To troubleshoot, check wiring and connections, ensuring they are secure and undamaged. Inspect the gas valve for faults. If issues persist, consult a professional technician for a precise diagnosis.

Regular checks and addressing error codes like F02 promptly can prevent disruptions and contribute to the longevity of your heating system. A well-maintained furnace ensures consistent warmth.

Answers To Key Questions

What are the codes on a Goodman furnace?

Goodman furnace error codes can vary depending on the model. Common error codes include issues related to pressure switches, limit switches, flame sensors, or other components. Consult your Goodman furnace manual or the unit’s control board for a list of specific error codes and their meanings.

How do I reset my Goodman error code?

To reset a Goodman error code, turn off the power to the furnace, wait for a few minutes, and then turn it back on. Refer to your Goodman furnace manual for model-specific reset instructions. If the error persists, consult the manual or contact Goodman technical support for assistance.

What is the code e02 on a Goodman furnace?

Error code E02 on a Goodman furnace usually indicates a high-temperature limit switch open. This may be due to overheating or other issues causing the furnace to exceed safe temperature limits. Consult your Goodman furnace manual for specific troubleshooting steps and recommendations.

What does code 2 mean on a furnace?

The meaning of code 2 on a furnace can vary by manufacturer and model. It’s important to refer to the specific furnace manual or control board for accurate information. In general, code 2 could indicate issues with the ignitor, gas supply, or other ignition-related components. Check the manual for troubleshooting steps or contact the manufacturer for guidance.

Final Thoughts

When your Goodman furnace communicates in the secret language of F02, fear not! It’s likely telling you there’s an issue with the pressure switch lacking enough vacuum to close, hindering the furnace from its heating duties. Whether it’s a blocked flue, a feeble-induced draft motor, or just some finicky switch contacts, we’ve got you covered. 🔍

Regular maintenance is the hero here, preventing issues and ensuring your furnace stays in top-notch shape. Remember, this is just a glimpse into the full guide on mastering Goodman Furnace Code F02. For the complete scoop and expert tips, dive into the detailed article. Stay warm and worry-free.

I’m Justin Taylor, your HVAC aficionado at thermostatinghub.com. I’m not just a writer; I’m your problem-solving partner for all things thermostat-related. Join me on my blog for stories that unravel the mysteries of heating and cooling. Let’s turn your HVAC puzzles into tales of comfort and control!