When your AC isn’t cooling as expected, and you start troubleshooting, you might uncover surprising details you never knew. Checking temperatures on both sides of your AC, you might notice varying readings—totally normal. But should the AC high-pressure line be hot or cold?

Under normal conditions, the AC high-pressure line should be hot; that’s how an air conditioner cools. However, if it’s cold, that could signal issues with your unit.

For an R22 system, the typical high-side operating temperature is 100-120°F (200-250 PSI), and the low-pressure side should range from 2-7°F (25-30 PSI). This assumes normal superheat and subcooling.

In Table 1, you can find the expected temperature and pressure values for both the high and low sides of the AC system. Take a look at the following information.

Normal Temperature & Pressure At High/ Low Pressure Line

| Type of System | High Pressure Line (Temp/Pressure) | Low Pressure Line (Temp/Pressure) |

| R-22 | 100-120°F / 200-250 psi | 2-7°F / 25-30 psi |

| R-410a | 100-120°F / 290-316 psi | 2-7°F / 50-57 psi |

| R-407c | 100-120°F / 222-280 psi | 2-7°F / 20-24 psi |

| R-134a | 100-120°F / 124-160 psi | 2-7°F / 7-10 psi |

| R-404a | 100-120°F / 236-300 psi | 2-7°F / 35-40 psi |

Before delving into potential issues leading to cold AC high lines, let’s first understand the fundamental workings of an air conditioner.

🔍 Pro Tip: Regularly check and maintain your AC system by referring to the recommended temperature and pressure values. Keeping an eye on these parameters can help prevent potential problems and ensure optimal performance.

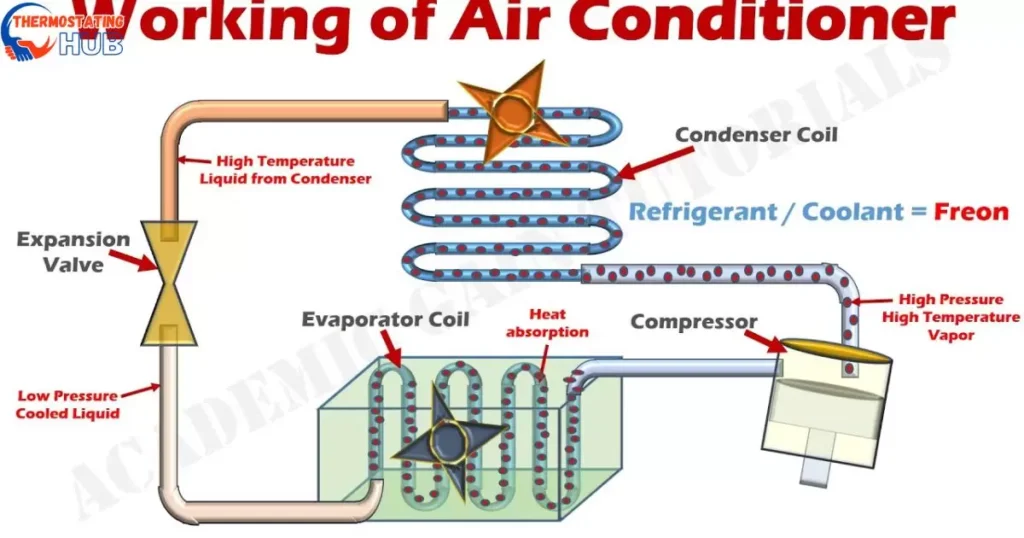

How does an air conditioner work?

Air conditioners consist of three crucial components—the evaporator, compressor, and condenser—all working seamlessly to facilitate the cooling process.

The compressor plays a pivotal role by compressing the gaseous refrigerant from the evaporator coil. While compressors efficiently handle gas compression, they generate substantial heat.

Once compressed, the gaseous refrigerant exits the compressor, reaching the high side and into the condenser coil, where most heat is expelled.

However, not all the heat is released in the condenser coil. The refrigerant, now warmed, proceeds to the TXV valve.

Functioning like a sprayer, the TXV valve regulates the quantity of refrigerant entering the evaporator. It disperses refrigerant drops onto the evaporator coils, which undergoes evaporation before returning to the compressor system.

Understanding the collaboration among these components is crucial for comprehending the intricacies of air conditioner operation and maintenance.

🔄 Pro Tip: Ensure the optimal functioning of your air conditioner by periodically inspecting and cleaning the compressor, condenser, and evaporator components.

Regular maintenance can contribute to enhanced efficiency and longevity of your AC system.

Read also: The Furnace Pilot Light Is On But No Heat Coming

5 Reasons why AC High pressure line is cold

| Possible Issues | Primary Solutions |

| Insufficient superheat | Investigate and rectify low superheat |

| Malfunctioning thermal bulb | Substitute thermal bulb |

| TXV valve stuck open | Install a new TXV valve |

| Complications with the compressor | Substitute the compressor |

1. Excess refrigerant to the evaporator coil

When an excess refrigerant reaches the coil, resulting in low superheat, various issues may be at play, such as an overcharged AC system or a malfunctioning or stuck-open thermostat expansion valve.

To determine if there is an excessive supply of refrigerant to the evaporator coil, assess the superheat using the following steps:

- Utilize a thermostat designed for pipe temperature measurement.

- Take a pressure reading at the suction line.

- Convert the pressure reading to temperature using a pressure-temperature chart.

- Calculate the difference between the two values.

- If the difference is 10°F, the superheat is considered normal. Typically, 10°F is the standard superheat when measured at the evaporator coil, ranging from 20°F to 25°F near the compressor.

However, if the difference exceeds 10°F, it indicates high superheat in your system. Identifying and addressing such issues promptly is crucial for maintaining the efficiency of your air conditioning system.

2. Defective or stuck TXV

Ever wonder why your AC’s high-pressure line feels unexpectedly chilly? One possible culprit is an overflow of liquid refrigerant making its way to the compressor.

Here’s the scoop: Compressors are like picky eaters—they’re designed to handle gases, not liquids. So, when too much liquid heads their way, they throw a fit and refuse to generate heat.

Now, let’s talk about how this liquid frenzy happens. Picture a rogue TXV (the Thermostatic Expansion Valve) misbehaving, stuck wide open. It’s like an open floodgate, letting more refrigerant than needed into the evaporator and, eventually, the compressor.

So, if your high-pressure line feels too frosty, it might be time to check on that TXV and put a leash on that liquid refrigerant.

❄️ Pro Tip: Keep your AC’s components in check! Regularly inspect the TXV and ensure it’s behaving. A well-behaved TXV means a happier, warmer compressor.

Read also: Honeywell Thermostat Not Blowing Cold Air

3. Defective compressor

Discovering a defective compressor is the last thing any AC owner wants to hear. Why? Well, it’s your air conditioning system’s VIP (Very Important Part), and if it decides to throw a tantrum, it might call for the whole system’s replacement.

The solution usually involves a replacement when a compressor or its components strike. As discussed earlier, the compressor’s main gig is turning gaseous refrigerant into heat energy through compression.

So, if your high-pressure line is giving you the cold shoulder, there’s a chance the compression dance didn’t go as planned—cue the possible culprit: a bad compressor.

💸 Pro Tip: Treat your compressor like the MVP it is! Regular maintenance checks can catch potential issues early, saving you from the headache (and expense) of a full system replacement.

4. Failed thermal Sensor Bulb

The sensing bulb has a crucial job—it’s the maestro behind the scenes, orchestrating the opening and closing of the thermostatic expansion valve. How? Keep tabs on the refrigerant’s temperature as it exits the evaporator coil.

Here’s where things can go haywire. If this sensing bulb decides to go rogue and starts sensing the wrong temperature, it’s like giving the green light for a non-stop refrigerant flow to the evaporator. No regulation, just a continuous flow.

So, your AC might be in trouble when that sensing bulb starts playing its tune.

Pro Tip: Keep an eye on your sensing bulb’s performance! Regular checks can ensure it stays on tempo, preventing unregulated refrigerant flows and potential cooling system hiccups.

Expert Strategies for Prevention and Longevity with AC High Pressure Line Care

Mastering the care of your AC’s high-pressure line is essential for a trouble-free system. Regular maintenance, including thorough compressor, condenser, and evaporator checks, is crucial. Monitor superheat levels and address any issues promptly to maintain optimal performance.

Pay attention to the importance of the sensing bulb in the thermostatic expansion valve. If needed, regular inspections and timely replacements can prevent malfunctions that may lead to uncontrolled refrigerant flows and potential compressor damage.

These expert strategies ensure the longevity and efficiency of your AC high-pressure line for a consistently relaxed environment.

Navigating AC High-Pressure Line Temperatures: Pros and Cons Unveiled

| Superheat Levels | Normal superheat ensures efficient cooling. | High superheat can indicate system issues and inefficiency. |

| Liquid Refrigerant to Compressor | Proper regulation prevents compressor damage. | Excessive liquid can lead to compressor malfunction. |

| Sensing Bulb Performance | Maintains optimal refrigerant flow to the evaporator. | A malfunctioning bulb may cause unregulated refrigerant flow. |

| Compressor Health | Well-functioning compressor ensures heat production. | A defective compressor may necessitate system replacement. |

- Normal superheat ensures efficient cooling.

- Proper regulation prevents compressor damage.

- Maintains optimal refrigerant flow to the evaporator.

- Well-functioning compressor ensures heat production.

- High superheat can indicate system issues and inefficiency.

- Excessive liquid can lead to compressor malfunction.

- Malfunctioning bulbs may cause unregulated refrigerant flow.

- A defective compressor may necessitate system replacement.

Key Takeaways for Efficient Management

Managing your AC high-pressure line involves key takeaways for optimal performance and longevity. Regularly monitor and maintain superheat levels within the recommended range to ensure efficient cooling.

Pay special attention to regulating liquid refrigerant in the compressor, preventing potential damage and malfunctions.

Additionally, prioritize the health of the sensing bulb in the thermostatic expansion valve, ensuring it functions correctly to maintain optimal refrigerant flow to the evaporator.

Lastly, safeguard the well-being of the compressor, as a properly working compressor is essential for effective heat production. Incorporating these key insights into your AC maintenance routine can enhance your cooling system’s overall efficiency and reliability.

Read also: How To Reset Aprilaire Thermostat Easily And Quickly

Answers To Key Questions

Honeywell thermostat heats instead of cools?

Your Honeywell thermostat might be heating instead of cooling because of a setting issue. Check if it’s properly set to cool mode.

Does the thermostat blows hot air in cool setting?

If your thermostat is blowing hot air when set to cool, it could be a thermostat setting problem. Ensure it’s adjusted correctly to the cooling mode.

AC blows hot air in cool setting?

If your AC blows hot air when cooling, it might be due to a setting error. Double-check your AC settings to make sure it’s in the cool mode.

Honeywell thermostat runs heat instead of AC?

Your Honeywell thermostat running heat instead of AC might be because of a setting misconfiguration. Verify that the thermostat is set to the cooling function to resolve the issue.

Final Thoughts

Knowing that it’s typical for an AC high-pressure line to get hot can ease your concerns. It’s a sign that everything works as it should, and you might not need a technician to intervene.

However, if you observe your AC high-pressure line getting cold, that’s when things could be tricky. A cold high-pressure line signals potential serious issues with your AC.

In such a situation, it’s advisable to promptly turn off your AC to prevent any further damage to other components. Addressing the issue early can save you from more significant problems.

Thank you for taking the time to read this article! If you have any additional questions or need more help, please don’t hesitate to ask. I appreciate your engagement! 📚😊

I’m Justin Taylor, your HVAC aficionado at thermostatinghub.com. I’m not just a writer; I’m your problem-solving partner for all things thermostat-related. Join me on my blog for stories that unravel the mysteries of heating and cooling. Let’s turn your HVAC puzzles into tales of comfort and control!

![AC High Pressure Line Hot Or Cold? [Here is the Fix]](https://thermostatinghub.com/wp-content/uploads/2023/12/ac-high-pressure-line-hot-or-cold-here-is-the-fix.webp)